Prevent Marine Growth with the Chloropac® System

Are you experiencing increased marine growth in your seawater piping, heat exchangers, sea chests, or coolers? Elevated seawater temperatures could be the cause of this problem. The Chloropac® Mk2M system is one of the only two effective solutions available on the marker today. Discover how we can support you in maintaining your vessel’s systems.

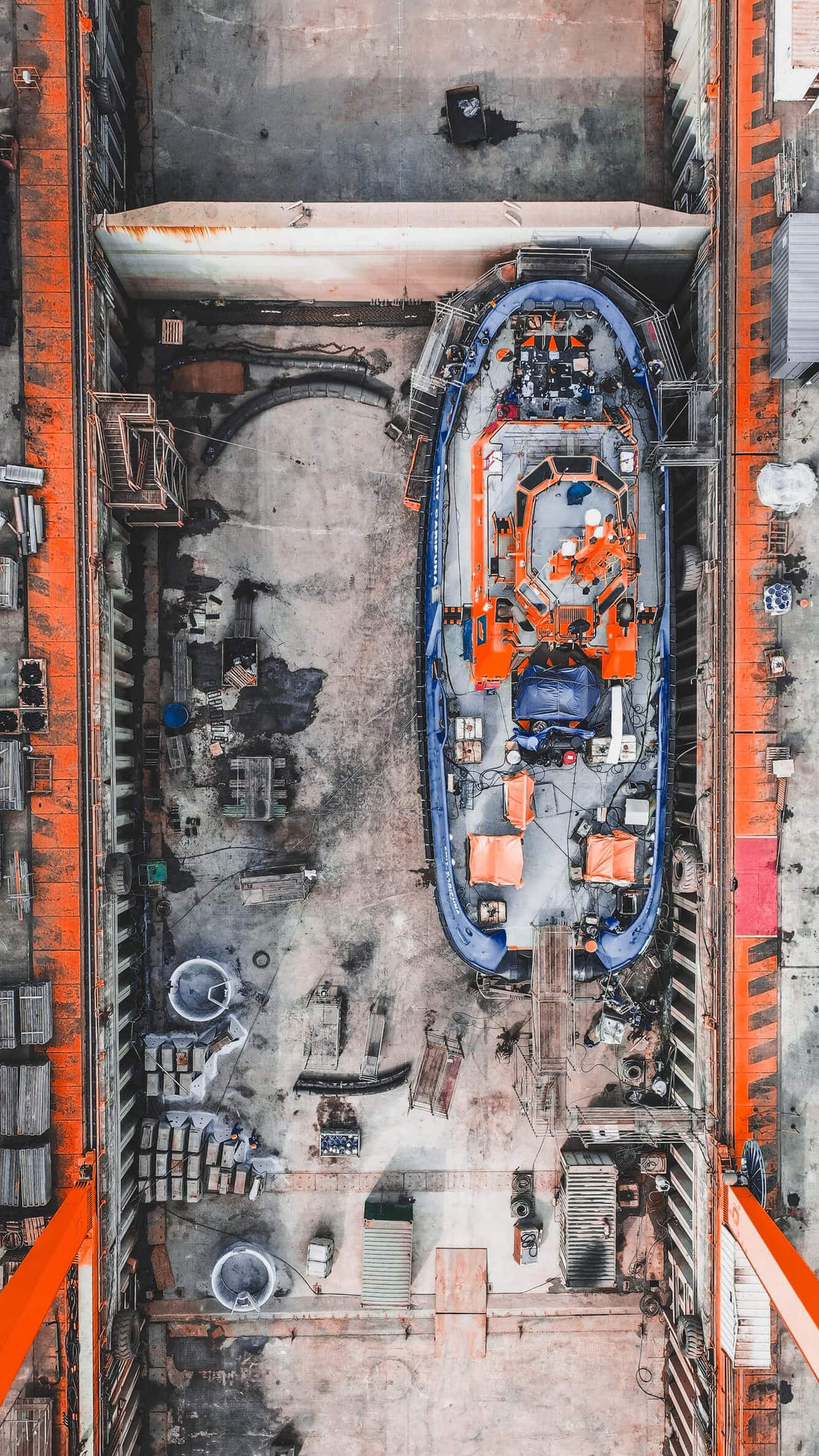

Typical Chloropac® System Shipboard Installation

The MGPS Mk2M Chloropac® sodium hypochlorite generating system prevents marine growth in seawater piping, heat exchangers, sea chests, and coolers. Ship owners and operators prefer the MGPS Mk2M system, with thousands of installations worldwide. Continuous low-level hypochlorination proves more effective than other marine growth prevention methods. Chloropac MGPS has earned trust in the marine market for over 40 years.

The MGPS Mk2M Process

A small amount of seawater, 5.7m³/hr (25 GPM), constantly pressurized, passes at high velocity through MGPS Mk2M electrolytic cells, converting part of the salt to sodium hypochlorite. This solution returns to the sea chest, mixing with incoming seawater. The cooling water now contains a trace residual sufficient to prevent marine organism growth, keeping all circuits—from intake to discharge—free from fouling. The system can interconnect with seawater circulating pumps to automatically adjust sodium hypochlorite output to suit on-board flow rates.

Comparison MGPS Mk2M to Other Methods

Effective Dosage |

||

|

The Chloropac electrochlorination system effectively controls both micro and macro fouling organisms by low continuous dose of 0.5 ppm or less. Additionally, it ensures efficient marine growth prevention

|

In contrast, copper ion-type systems claim a dose rate of 1 ppb suffices for all marine growth. However, a dose rate of ~20 ppb is actually needed to control macro fouling. Additionally, continuous dissolution of copper and aluminum does not effectively combat micro fouling. | |

Cell Longevity and Maintenance Costs |

||

| The Chloropac system uses platinum-on-titanium electrolytic cells (anodes) to produce sodium hypochlorite from seawater. These cells are warranted for five years, but typically last around seven years. | Conversely, copper-based systems use “sacrificial anodes” that dissolve quickly, requiring replacement every 12-24 months at a high cost. Therefore, ongoing consumable and maintenance costs are lower with the Chloropac system. | |

Control and Environmental Impact |

||

| Chloropac system controllers can be adjusted manually or automatically to regulate hypochlorite production based on demand, allowing for zero or near-zero residual overboard discharge. | On the other hand, copper anodes dissolve continuously, discharging copper overboard and adding heavy metal pollutants to the ocean. | |

Chemical Handling and Safety |

||

| The Chloropac system produces sodium hypochlorite using only ambient seawater, eliminating the need to store biocides or precursor chemicals on board. All produced sodium hypochlorite is directly injected into the sea chests, simplifying purchasing, storage, handling, and chemical logistics. | In contrast, chemical injection systems require the storage and handling of highly corrosive and toxic chemicals, creating additional storage and safety hazards on board. | |

Conclusion

In conclusion, the Chloropac system not only provides superior control but also offers lower maintenance costs and reduced environmental impact. Furthermore, it simplifies chemical handling compared to alternative methods of marine growth prevention.

Contact Us for More Information

If you have any questions or require spare parts for your Evoqua system.

SPARE PARTS AVAILABLE FROM STOCK:

Evoqua PN |

DWG PN |

VV PN |

Description |

| W3T344631 | 4-10176 | 12997 | Cell Assembly MK2M |

| W2T624713 | 5/0849 | 10118 | Spacer pips |

| W3T290804 | 5/1000 | 11525 | Cell Anode MK2M |

| W2T624757 | 5/1001 | 11526 | Cell Cathode MK2M |

| W3T331066 | 5/1002 | 11527 | Cell Bi-polar MK2M |

| W2T624759 | 5/1003 | 11602 | Union body MK2M |

| W2T624760 | 5/1004 | 11599 | Union nut MK2M |

| W2T624761 | 5/1005 | 10122 | Split collar MK2M |

| W2T625195 | 5/1005 | 10112 | O-ring MK2M |

| W2T624762 | 5/1007 | 10123 | End cone MK2M |

| W2T624763 | 5/1008 | 11511 | Titanium pin MK2M |

| W2T624764 | 5/1009 | 10128 | Locating sleeve MK2M |

| W2T624765 | 5/1010 | 11507 | Union end MK2M |

| W2T624788 | 5/1041 | 11581 | Inner cell spacer MK2M |

| 12624 | Flow indicator DN25 | ||

| 12625 | Flow indicator DN40 |

STANDARD VALVES:

Evoqua PN |

DWG PN |

Spec PN |

Description |

| W2T630794 | 6D-16511 | 6S-13913/3 | Shipside valve DN25 ANSI 150 |

| W2T630795 | 6D-16511 | 6S-13913/4 | Shipside valve DN40 ANSI 150 |

| W2T850076 | 6D-16511 | 6S-13913/5 | Shipside valve DN50 ANSI 150 |

| W2T630801 | 6D-16768 | 6S-13929/3 | Shipside valve DN25 EN1092 |

| W2T630802 | 6D-16768 | 6S-13929/4 | Shipside valve DN40 EN1092 |

| W2T630803 | 6D-16768 | 6S-13929/5 | Shipside valve DN50 EN1092 |

| W2T631206 | 6D-19764 | 6S-30766/2 | Shipside valve DN25 JIS 10K |

| W2T631207 | 6D-19764 | 6S-30766/3 | Shipside valve DN40 JIS 10K |

| W2T631208 | 6D-19764 | 6S-30766/4 | Shipside valve DN50 JIS 10K |

| W2T625162 | 6D-17405 | 6S-13914/2 | Check Valve DN25 ANSI 150 |

| W2T625163 | 6D-17405 | 6S-13914/3 | Check Valve DN40 ANSI 150 |

| W2T802376 | 6D-17405 | 6S-13914/4 | Check Valve DN50 ANSI 150 |

| W2T630806 | 4-24357 | 6S-13930/2 | Check Valve DN25 EN1092 |

| W2T630807 | 4-24357 | 6S-13930/3 | Check Valve DN40 EN1092 |

| W2T630808 | 4-24357 | 6S-13930/4 | Check Valve DN50 EN1092 |

| W2T631117 | 6D-17750 | 6S-30629/2 | Check Valve DN25 JIS 10K |

| W2T631118 | 6D-17750 | 6S-30629/3 | Check Valve DN40 JIS 10K |

| W2T631119 | 6D-17750 | 6S-30629/4 | Check Valve DN50 JIS 10K |

| W2T821954 | 6D-19949 | 6S-32995/2 | Diaphragm Valve DN25 ANSI 150 |

| W2T821955 | 6D-19949 | 6S-32995/3 | Diaphragm Valve DN40 ANSI 150 |

| W2T821956 | 6D-19949 | 6S-32995/4 | Diaphragm Valve DN50 ANSI 150 |

| W2T821958 | 6D-19949 | 6S-32995/6 | Diaphragm Valve DN25 EN1092 |

| W2T821959 | 6D-19949 | 6S-32995/7 | Diaphragm Valve DN40 EN1092 |

| W2T821960 | 6D-19949 | 6S-32995/8 | Diaphragm Valve DN50 EN1092 |

| W2T625176 | 4-21329 | 6S-13536/2 | Diaphragm Valve DN25 EN1092 |

| W2T625584 | 4-21329 | 6S-13536/3 | Diaphragm Valve DN40 EN1092 |

| W2T630722 | 4-21329 | 6S-13536/4 | Diaphragm Valve DN50 EN1092 |

| W2T630811 | 6D-19757 | 6S-13939/1 | Diaphragm Valve DN25 JIS 10K |

| W2T630812 | 6D-19757 | 6S-13939/2 | Diaphragm Valve DN40 JIS 10K |

| W2T630813 | 6D-19757 | 6S-13939/3 | Diaphragm Valve DN50 JIS 10K |

Send your inquiry to info@venteville.com