Grinding & Machining

Comprehensive Solutions

Chris-Marine offers complete solutions for diesel and gas engine maintenance, designed to minimize downtime and reduce costs. Our extensive Grinding & Machining portfolio is developed to overhaul and restore cylinder heads, liners, and sealing surfaces with precision.Cylinder Heads Maintenance

Maintaining cylinder heads according to engine makers’ specifications is crucial for engine performance. Neglecting this can lead to significant performance issues and costly repairs. Fortunately, Chris-Marine provides a range of machines that make grinding and machining cylinder heads efficient and accurate, ensuring optimal engine operation.Cylinder Liners & Sealing Surfaces

Our Grinding & Machining equipment for cylinder liners includes honing and deglazing machines, as well as wave cut grinding and wear edge milling tools. These tools restore 2-stroke and 4-stroke liners efficiently. We offer both in-situ and honing rig solutions, complemented by high-quality ceramic and diamond honing stones. To enhance the honing process, our honing liquid prevents residue build-up, ensuring smooth operation. For sealing surfaces, our machines meet engine manufacturers’ specifications, guaranteeing precise maintenance. Proper machining helps avoid engine performance drops and unnecessary downtime. With our equipment, keeping your engine in top condition becomes both accurate and efficient.Contact Us for More Information

If you have any questions or require spare parts for your Chris-Marine system. Contact us.

Automatic honing machine for restoration of medium speed engine cylinder liner geometry and surface structure.

Honing machine for restoration of medium speed engine cylinder liner geometry and surface structure.

For grinding of sealing surfaces between cylinder head and cylinder liner, and between cylinder liner and engine frame on medium bore diesel engines.

A combined machine for in-situ machining of valve seats and seat recesses on 4-stroke medium speed diesel engines.

Portable lathe for in-situ machining of valve seats on 4-stroke diesel engines.

Designed for easy removal of worn valve seats from cylinder heads.

Designed and developed for grinding of valves and valve seats on 2-stroke diesel engines.

For grinding of valves on high and medium speed diesel engines, and valves and valve seats on smaller 2-stroke diesel engines, in existing lathes.

For grinding of valve spindles on medium and high speed diesel engines.

For grinding of valve spindles on medium and high speed diesel engines.

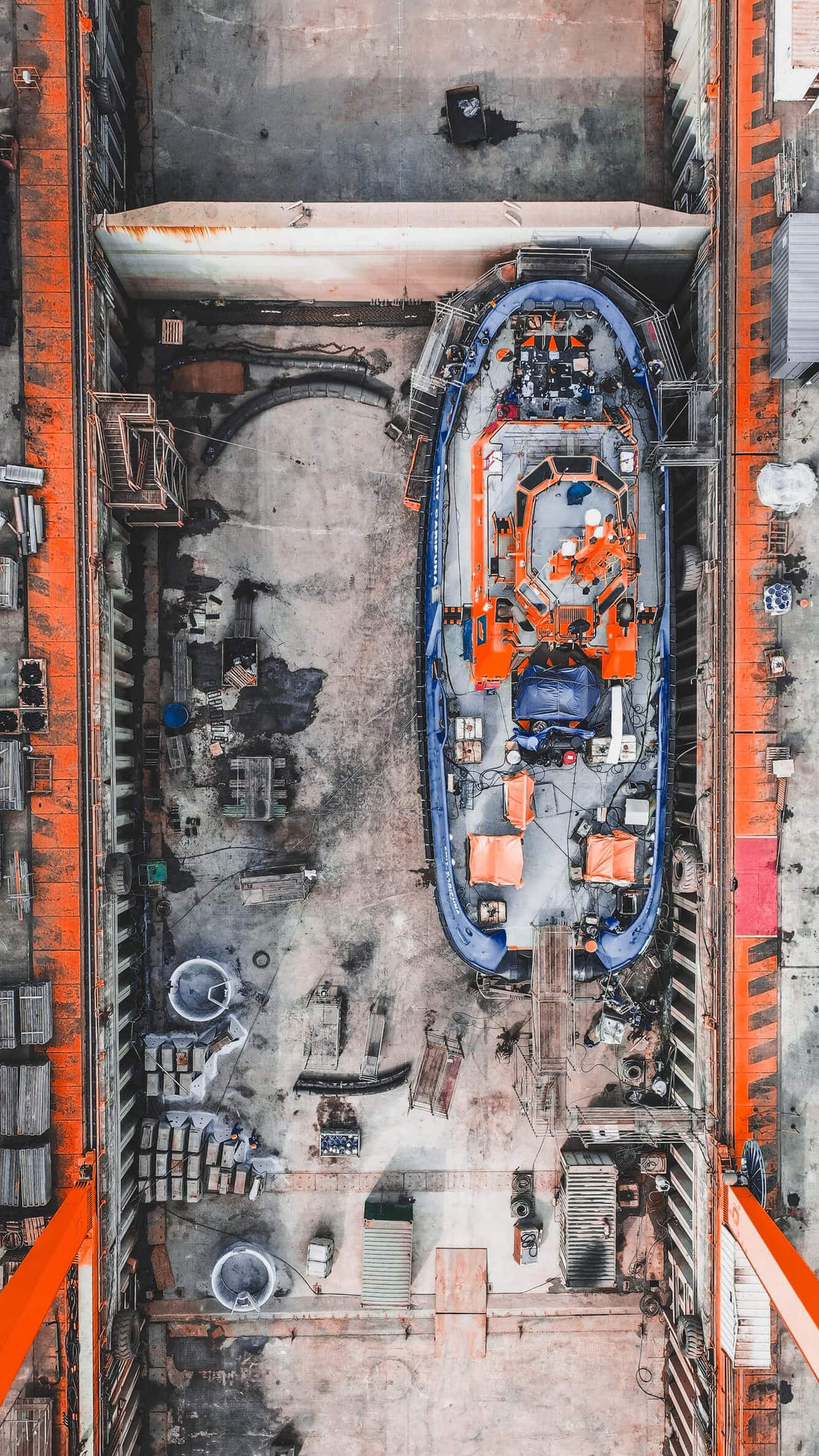

The Chris-Marine range of working rigs has been developed for safe and efficient maintenance of 2-stroke and 4-stroke engine parts.