EGR Water Treatment

Regulatory Drivers for Emission Reduction

To reduce ship exhaust emissions, air emission regulations are advancing the development of engine technologies, exhaust abatement systems, and EGR water treatment. Consequently, internal combustion engine manufacturers utilize various techniques to lower NOx emissions. The most common approaches involve reducing NOx at the source and treating exhaust gas after combustion to meet the IMO Tier III standard.The Role of Exhaust Gas Recirculation

Exhaust gas recirculation (EGR) redirects about 30–40% of exhaust gases back to the engine’s intake. This process lowers the oxygen (O2) content in the incoming air while increasing carbon dioxide (CO2) levels. As a result, the peak combustion temperature significantly drops, leading to reduced NOx formation.Maintaining EGR System Efficiency

To prevent corrosion in the combustion chamber and EGR components, recirculated exhaust gases must be cleaned and cooled before re-entering the engine. The required cleaning level depends on the sulphur content of the fuel used. Fresh water cleans and cools the recirculated exhaust gas, but this water must be treated to maintain its effectiveness. Additionally, the combustion process generates condensate that must be drained and treated from the EGR unit.

Efficient Flocculation for Bilge and EGR Bleed-Off Water

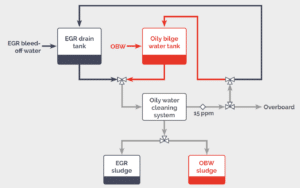

The CD EGR system offers a highly effective solution for cleaning both EGR and Bilge water using advanced flocculation technology. The combined EGR and Bilge Water Treatment system streamlines operations, reducing equipment, installation, operational costs, and the overall CO2 footprint. Despite the different MARPOL Annexes governing bilge water and EGR bleed-off water, the system ensures complete segregation, with separate holding and sludge tanks. System automation, including class-approved segregation valves, prevents any mixing of waste streams and sludge during treatment. From the control panel, operators can effortlessly select the waste stream for treatment, ensuring accurate discharge monitoring, record-keeping, and compliance with MARPOL standards through optional integration with the WhiteBox® system.

Process Overview

The CD unit can handle either EGR bleed-off or bilge water, depending on the selection from a control panel. Three three-way valves, connected to a selector switch, ensure these waste streams never mix. EGR bleed-off water is collected in a cascade-type drain tank, which includes heating coils to maintain a temperature of 40-55°C. Solid sensors in the tank detect soot solidification. Segregated sludge tanks are provided to meet MARPOL requirements. Once processed, wastewater is discharged overboard through a WhiteBox® system, which logs vital data such as tank levels, valve positions, oil content, and discharge volumes, ensuring seamless compliance and traceability.

By integrating bilge and EGR bleed-off water treatment, the CD EGR system ensures operational efficiency while maintaining environmental and regulatory compliance.

Contact Us for More Information

If you have any questions or require spare parts for your Marinfloc system.

Key Features of Combined EGR and Bilge Water Treatment System

- Lower CAPEX as there is no need to procure a separate OWS.

- Lower OPEX, less documentation, classification cost and spare parts.

- Space-efficient with a smaller footprint.

- One high-end separator for two waste streams.

- Lower cost for commissioning.

Advantages of Marinfloc OWS system

- Flocculation technology. No cartridge filters nor centrifuges required.

- Adjustable to the ship specific EGR bleed-off water composition

- Low energy consumption for low carbon footprints

- Low operational cost

- Stainless steel material

- Made in Sweden

Applied regulations

- MEPC.307(73) regulated EGR bleed off water

- MEPC.107(49) regulated bilge water

Seamless Integration of Marinfloc WTS with MAN-ES EGR System

Marinfloc introduces the WTS, engineered for seamless integration with MAN-ES Exhaust Gas Recirculation (EGR) systems. Leveraging over two decades of experience, Marinfloc’s proven flocculation process ensures that the WTS not only meets but exceeds operational standards. Crafted from durable stainless steel, it combines reliability and innovation to deliver precision and long-lasting performance. With intuitive digital functionalities, the WTS simplifies documentation, streamlining operations for ship crews. Additionally, for vessels with MAN-ES engines, the WTS can also serve as an efficient bilge water separator, enhancing operational flexibility.

Versatile Integration Options

Standalone EGR Bleed-Off Water Treatment

The WTS is specifically designed to treat bleed-off water from the EGR system, ensuring optimal water quality and compliance with environmental regulations.

Combined EGR and Bilge Water Treatment (WTS→CD-EGR)

This dual-purpose solution integrates both EGR bleed-off water treatment and bilge water separation. It can be purchased as a combined unit or upgraded from a standalone WTS, ensuring full compliance with bilge water separation standards.

Marinfloc’s WTS provides shipowners with flexible solutions tailored to meet modern operational needs, offering both standalone and integrated wastewater treatment options.

Contact Us for More Information

If you have any questions or require spare parts for your Marinfloc system.

Advantages of Marinfloc WTS system

- Utilizes flocculation technology, eliminating the need for cartridge filters and centrifuges

- Approved for both MAN-ES and WinGD iCER

- Functions as both an EGR bleed-off water treatment and, with upgrades, a bilge water separator

- Designed for low energy consumption, contributing to reduced carbon footprints.

- Seamless integration with WhiteBox® for combined bilge water treatment

- Advanced HMI system with remote service and assistance, ensuring you’re always connected and supported

Seamless Integration of Marinfloc WTS with WinGD iCER System

Marinfloc introduces the WTS (Wastewater Treatment System), designed for seamless integration with WinGD’s iCER system. Backed by over two decades of industry expertise, Marinfloc’s proven flocculation process ensures the WTS surpasses operational expectations. Crafted from durable stainless steel, the system is both reliable and robust. Moreover, it features intuitive digital functionalities, simplifying documentation for ship crews. As iCER technology focuses on reducing methane slip and fuel consumption, it aligns perfectly with Marinfloc’s commitment to sustainability and operational efficiency. WTS For WinGD iCER

WinGD’s iCER Technology: Enhancing Efficiency and Sustainability

Intelligent Control through Exhaust Recycling (iCER) is WinGD’s innovative solution for X-DF2.0 engines. Tailored for the X-DF Otto cycle engine technology, iCER improves fuel efficiency, reduces methane slip, and enhances combustion stability. In a maritime industry facing increasingly stringent environmental regulations, iCER offers a forward-looking solution that ensures compliance and promotes sustainability.

Benefits of Integrating WTS with iCER

When Marinfloc’s WTS integrates with WinGD’s iCER, it provides a comprehensive wastewater treatment solution that complements the environmental benefits of the iCER technology. This combination further reduces the vessel’s environmental footprint while ensuring compliance with regulatory standards. As a result, shipowners not only meet requirements but also contribute meaningfully to maritime sustainability.

Adaptability and Cost-Effectiveness

Unlike traditional systems operating at fixed capacities, the WTS system is adaptable. It automatically adjusts its discharge capacity based on water generation, ensuring a steady supply of treated water to the iCER system. Managed by a Discharge Control Unit specifically designed for the WIN GD application, this flexibility reduces energy consumption, lowers consumable usage, and minimizes the vessel’s CO2 footprint. This adaptability makes the WTS system a cost-effective and sustainable solution for shipowners and operators.

Contact Us for More Information

If you have any questions or require spare parts for your Marinfloc system.

Advantages of Marinfloc WTS system

- Utilizes flocculation technology, eliminating the need for cartridge filters and centrifuges

- Cost Savings: Reduced operational costs due to its adapable water treatment and minimized energy consumption.

- Approved for both MAN-ES and WinGD iCER

- Enhanced Sustainability: Lower CO2 footprint and reduced environmental impact.

- Operational Efficiency: Adaptable system that adjusts to water generation, preventing overloads.

- Seamless integration with WhiteBox® for combined bilge water treatment

- Advanced HMI system with remote service and assistance, ensuring you’re always connected and supported

OMD Recondition & Exchange Service

To maintain compliance with IMO Resolution MEPC.107(49) and ensure continuity, Marinfloc offers two cost-effective options for your OMD-24 – OMD-2005: Calibration and Exchange services.

Option 1 – OMD Cell Calibration

In this option, the client sends their OMD cell to Marinfloc. Once received, a Marinfloc-authorized engineer will calibrate the cell. After calibration, the OMD cell is returned within 14 days, ensuring minimal downtime and ongoing compliance.

Option 2 – OMD Exchange System

With the exchange option, Marinfloc sends a reconditioned and calibrated OMD cell from stock. Upon receiving the replacement, the client must return their old OMD cell within 60 days of the invoice. A credit will be issued once the old cell is returned.

Both options provide a reliable, efficient way to maintain your OMD unit’s performance while adhering to international regulations.

How to order

Download the pdf file to open the order form, select your options and send the form to info@venteville.com

Contact Us for More Information

If you have any questions.