Chris-Marine

Expertise in Engine Maintenance

For over five decades, Chris-Marine has specialized in designing, manufacturing, and selling maintenance equipment for 2- and 4-stroke diesel engines. Their products are known globally for their high quality and user-friendly design. With sales offices in Sweden, Denmark, Germany, Singapore, China, India, Japan, Ecuador, and the USA, Chris-Marine ensures close customer support worldwide. Additionally, their well-equipped workshops in Denmark, Germany, Sweden, Singapore, Shanghai, and the USA make them a trusted partner for engine care and maintenance.Solutions for the Future

Chris-Marine employs around 100 dedicated experts who continuously improve their products and services. Their mission is to help customers optimize engine performance, saving time and money while considering environmental impact. Under three strong brands—Chris-Marine®, Obel-P®, and LEMAG®—they offer six product portfolios:- Monitoring

- Cleaning

- Grinding & Machining

- Fuel System Maintenance

- Power Packs

- Accessories & Consumables

Contact Us for More Information

If you have any questions or require spare parts for your Chris-Marine system. Contact us.

Automatic honing machine for restoration of medium speed engine cylinder liner geometry and surface structure.

Precision Coating Thickness Measurement with CTM

Chris-Marine’s Coating Thickness Measurement tool (CTM) delivers precise readings of coating thickness on both magnetic and non-magnetic base materials. This tool is essential for assessing the remaining lifetime of coated piston rings in 2-stroke engines. With a liner time scale of approximately 1000 Rh and a measurement time of just 15 minutes per liner, CTM provides fast, accurate results.

Key Benefits for Condition-Based Monitoring

CTM is designed for condition-based monitoring of piston rings, ensuring optimal engine performance. It measures non-magnetic coatings on magnetic materials, such as chromium-plated or plasma-coated cast iron, and non-magnetic coatings on non-magnetic materials, like plastic-coated stainless steel. The tool automatically detects the base material’s type, simplifying the process for users.

Compact, user-friendly and enables reliable measurements even in hard-to-reach areas. This makes it a practical choice for in-situ, non-destructive testing, contributing to more efficient maintenance planning.

The CTM combines ease of use with advanced technology, providing accurate measurements and helping optimize engine maintenance strategies.

Contact Us for More Information

If you have any questions or require spare parts for your Chris-Marine system.

Mechanical Crankshaft Deflection Gauge

The Mechanical Crankshaft Deflection Gauge, CONTROLmag® I&II, provides a reliable way to check crankshaft bearing alignment and deflection in all types of engines. Designed for precision and durability, this gauge features robust construction and hardened measuring tips, ensuring accurate measurements across various applications. Its compact design allows easy adjustment of the gauge position, making it user-friendly and efficient.

Versatile and Durable for Engine Maintenance

The CONTROLmag® I&II is equipped to measure crankshaft distortion and, with the optional rounded tips, can also be used to assess cylinder wear. Whether working with smaller or larger engines, the gauge offers two measuring range options to suit your specific needs:

- 21900002: Measuring range of 60 mm – 300 mm

- 21900042: Measuring range of 60 mm – 500 mm

The gauge is packaged in a ready-to-use case, allowing for quick deployment in any setting, from workshops to onboard engine rooms.

By combining precision technology with a durable, versatile design, the Mechanical Crankshaft Deflection Gauge ensures efficient maintenance and reliable engine performance.

Contact Us for More Information

If you have any questions or require spare parts for your Chris-Marine system.

Product Features

- Precision Bearing Alignment: Easily checks crankshaft deflection for accurate alignment.

- Durable Construction: Hardened tips ensure longevity and precision in challenging environments.

- Cylinder Wear Measurement: Optional rounded tips enable the tool to measure cylinder wear as well.

- Easy-to-Adjust: Compact design simplifies adjustment and use in tight spaces.

- Wide Measuring Range: Choose between two options for different engine sizes, ranging from 60 mm to 500 mm.

LEMAG® DI-5 and LEMAG® DI-5C: Efficient Crankshaft Deflection Indicators

Chris-Marine’s LEMAG® electronic crankshaft deflection indicators, the DI-5 and DI-5C, provide time-saving solutions for efficiently checking crankshaft deflection. These tools allow users to identify potential problems early, thus avoiding costly engine repairs.

LEMAG® DI-5: Upgradeable and Reliable

Designed for frequent use, the LEMAG® DI-5 simplifies crankshaft deflection checks, ensuring efficient and reliable operation. Its transducer, combined with invar alloy extension bars, minimizes heat expansion, ensuring accurate results in a variety of conditions. Moreover, the DI-5 is portable, with rechargeable batteries and a durable case that enhances convenience.

A key feature of the DI-5 is its upgradeability. Users can upgrade it to the DI-5C without needing to replace the entire device, ensuring long-term usability and cost efficiency.

LEMAG® DI-5C: Advanced with Data Capabilities

The LEMAG® DI-5C enhances deflection measurement through its built-in microprocessor, allowing users to print and download measurement results directly to a computer. This functionality simplifies data tracking and analysis, making the DI-5C an ideal tool for maintenance teams. The device is supplied with a USB interface connection cable and software, adding even more flexibility.

For those needing cylinder liner measurements, the LEMAG® DI-5C offers an optional ovality kit. This kit allows measurement of cylinder liner ovality for diameters ranging from 180 to 600 mm and strokes up to 870 mm, with larger sizes available upon request.

Key Features:

- Invar alloy extension bars for minimal heat expansion

- Rechargeable batteries and sturdy case for easy portability

- DI-5 upgradeable to DI-5C without full device replacement

- DI-5C’s microprocessor allows printing and downloading of data

- Optional ovality kit for cylinder liner measurements (diameters: 180-600 mm, stroke: up to 870 mm)

Both the LEMAG® DI-5 and DI-5C offer reliable, efficient solutions for engine maintenance, ensuring accurate results and early problem detection.

Contact Us for More Information

If you have any questions or require spare parts for your Chris-Marine system.

LEMAG® ECI: Electronic Cylinder Pressure Indicator for Improved Engine Uptime and Cost Efficiency

The LEMAG® ECI is an advanced electronic cylinder pressure indicator designed to enhance engine uptime while reducing operating costs. It enables technicians to fine-tune, balance, and monitor both auxiliary and main engines, providing performance insights for all large 2- and 4-stroke engines running on natural gas, LPG, or HFO/MDO, as long as they have an indicator valve.

Key Features of LEMAG® ECI

The LEMAG® ECI excels in fine-tuning engine performance and lowering costs. Built to withstand harsh ship and power plant conditions, it allows continuous engine readings without overheating the sensor. By detecting problems early, it prevents costly downtime. Its optional crank angle sensor adds unmatched accuracy, ensuring reliable data.

This device is user-friendly, with an ergonomic handheld unit featuring a large color display. Technicians can confirm measurement success in real time, even while wearing gloves. Results can be transferred to a PC for further analysis or sent to superintendents for comparison with historical or reference data. The intuitive menus and step-by-step graphic instructions make it easy for new operators to handle.

For quality assurance, the LEMAG® ECI can be sent to Chris-Marine Germany for test and calibration, with a renewed certification provided every 12 to 24 months.

Two Configurations to Match Your Engine

LEMAG® ECI

This configuration provides accurate cylinder pressure measurements with automatic TDC detection for MIP and power calculation. It also features misfiring analysis and engine balancing functions. Equipped with a high-quality pressure sensor with a leak-proof, patented design and excellent thermal properties, it ensures precision and durability.

LEMAG® ECI-MS

The ECI-MS version includes the easy-to-mount MS Crank Angle Sensor for high-resolution crank angle measurements, making it ideal for low-speed engines. This ensures precise MIP and cylinder power calculations for optimal engine performance.

Both configurations of the LEMAG® ECI deliver reliable and efficient solutions for monitoring and optimizing engine operations.

Contact Us for More Information

If you have any questions or require spare parts for your Chris-Marine system.

For test of fuel injectors on 4-stroke engines.

Fuel valve test unit with digital read-out for test of fuel injectors for 2-stroke and 4-stroke engines.

For precision grinding of fuel pump and fuel valve components for diesel engines.

Ensuring Precision for Modern Diesel Engines

Today’s diesel engines face substantial loads as a result of high working pressures and increasing performance demands. To maintain efficiency and avoid potential failures, operators must grind sealing surfaces with precision to ensure a tight seal. Using thoroughly tested, high-quality grinding wheels is crucial for long-term engine performance.

Chris-Marine’s Proven Grinding Solutions

Chris-Marine carefully selects, rigorously tests, and proves its grinding wheels to deliver excellent results across various metal alloys, surface finishes, and workloads. Choosing the right grinding wheel is critical to achieving superior results. Each grinding wheel is a precision tool composed of thousands of cutting points made of abrasive grains, held together by a bonding matrix. Selecting the correct type of wheel for the job is essential for ensuring reliable engine performance.

Contact Us for More Information

If you have any questions or require consumables for your Chris-Marine system.

AVAILABLE GRINDING WHEELS:

Part Number |

Dimension DxTxH |

Colour |

Grinding Machine |

| 11373-01-01 | 152x15x32 | violet | LBD, 150S |

| 11373-02-01 | 76x30x32 | greyish-brown | LCD |

| 11373-02-02 | 76x30x32 | lightblue | LCD |

| 11373-04-04 | 152x51x32 | brownish-grey | CPS |

| 11373-04-05 | 152x51x32 | greenish-black | LBD, CPS |

| 11373-06-01 | 180x10x32 | white | BFG |

| 11373-07-01 | 178x51x32 | white | BFG |

| 11373-08-09 | 76x40x32 | white | CPL, CPM |

| 11373-08-10 | 76x40x32 | blue | CPL, CPM |

| 11373-10-07 | 15x8x8 | rose | PRG |

| 11373-11-07 | 15x5x8 | rose | PRG |

| 11373-12-02 | 76x10x32 | violet | 75H, HVG |

| 11373-12-03 | 76x10x32 | whitish-grey | 75H, HVG |

| 11373-15-03 | 38x19x6 | gray | MSD |

| 11373-16-04 | 38x19x6 | greyish-blue | HP, PSS |

| 11373-17-02 | 42x13x6 | blue | PSS |

| 11373-18-02 | 25x16x6 | white | MSD |

| 11373-19-01 | 16x13x6 | white | MSD |

| 11373-23-01 | 120x18x32 | white | CPL, CPM |

| 11373-24-02 | 108x18x32 | white | CPL, CPM |

| 11373-25-01 | 10x10x6 | rose | MSD |

| 11373-27-07 | 200x13x32 | blue | BSP |

| 11373-27-08 | 200x13x32 | white | BSP |

| 11373-29-01 | 66x25x25 | lightblue | LCD |

| 11373-33-01 | 75x30x32 | grey | CPL, CPM |

| 11373-38-01 | 32x19x6 | black | CPL, CPM |

Honing machine for restoration of medium speed engine cylinder liner geometry and surface structure.

Importance of Honing and Deglazing in Engine Overhauls

Many medium-speed engine makers recommend honing or deglazing during piston overhauls to prevent post-overhaul running issues. One of the key benefits of honing is reduced oil consumption, which is especially important in Otto-cycle gas engines. High oil consumption in these engines can lead to knocking problems, affecting performance. Honing Stones

For engines that are not worn but have glazed or polished cylinder liners—common when running on MGO, gas, or other low-sulfur fuels—deglazing is sufficient. This process refreshes the surface without altering cylinder geometry. However, when cylinder liners become worn, especially after a second piston overhaul in engines running on HFO, ovality and wear edges must be removed for optimal engine function. This more time-consuming process is called honing.

Choosing the Right Honing Stones

Honing time and stone consumption increase with larger cylinder diameters and stroke lengths. Diamond stones are more durable and remove material faster than ceramic stones, making them ideal for coarse honing of large or heavily worn engines. Conversely, ceramic stones provide excellent oil retention, making them essential for finishing the running surface structure.

Chris-Marine® offers a range of honing stones, rigorously tested and proven to deliver reliable performance for most engine types. Selecting the right stones ensures efficient engine maintenance and long-lasting results.

Contact Us for More Information

If you have any questions or require Honing Stones for your Chris-Marine system.

AVAILABLE HONING STONES:

Part Number |

Grain Size |

RA (≈) |

| 11373-20-01 | 80 | 0.7-2.0 |

| 11373-20-02 | 80 B | 0.7-2.0 |

| 11373-20-04 | 60 | 1.5-3.0 |

| 11373-20-05 | 60 B | 1.5-3.0 |

| 11373-20-07 | 46 B | 2.0-4.0 |

| 11373-20-10 | 46 B | 2.5-4.5 |

| 11373-20-13 | 46 B | 3.0-5.5 |

| 11373-20-14 | 36 B | 3.0-5.5 |

| 11373-20-16 | 36 B | 0.5-1.5 |

| 11373-20-17 | 220 | 0.7-1.0 |

| 11373-20-20 | 36 B | 3.0-5.5 |

| 11373-20-23 | 36 | 3.0-5.5 |

| 11373-20-26 | 400 | 0.4-0.8 |

| 11373-20-30 | 220 | 0.4-0.1 |

| 11373-20-34 | 220 | 0.4-1.0 |

| 11373-20-35 | 320 | 0.4-1.0 |

| 11373-20-36 | 400 | 0.4-0.8 |

| 11373-20-37 | 500 | 0.4-0.8 |

| 11373-20-39 | 80 | 1.1-1.5 |

| 11373-30-03 | Rough SD252/80 | 3.0-6.0 |

| 11373-30-04 | Medium SD181/100 | 1.5-2.5 |

| 11373-30-05 | Fine SD91/220 | 1.0-2.0 |

| 11373-30-07 | Medium/Fine SD107/180 | 1.2-2.2 |

High-Pressure Hoses

The OBEL-P high-pressure hoses provide excellent flexibility. Their low volumetric expansion contributes to a fast response time in hydraulic systems. Additionally, the smooth inner bores ensure minimal pressure drop, enhancing efficiency in various applications. Hoses & Couplings

Moreover, these hoses feature a long lifespan due to their kink-resistant, steel-reinforced construction and abrasion-resistant covers. Their small outside diameter and lightweight design make them ideal for use onboard vessels, in workshops, and at power plants. Furthermore, the high burst pressure, combined with optional protection covers and 120-degree angle packing surfaces, guarantees optimal safety during operation.

CEJN Couplings and Nipples

The OBEL-P CEJN 116/125 series couplings and nipples maintain high quality and meet the specifications set by engine manufacturers such as MAN Diesel and Wärtsilä. These components are designed to complement our high-pressure hoses, ensuring reliable connections and performance.

In summary, our OBEL-P hoses and CEJN couplings provide dependable performance, ensuring safety and efficiency in demanding environments. Choose our high-pressure solutions for unmatched flexibility and durability.

Contact Us for More Information

If you have any questions or require Consumables for your Chris-Marine system.

Product Features

- Pressure Range: Up to 2500 bar

- Low Volumetric Expansion

- High Quality

- Smooth Inner Bores

- Kink-resistant Steel-reinforced Construction

- Abrasion-resistant Covers

- Small Outside Diameter

- Superior Chemical Resistance

AVAILABLE HOSES & COUPLINGS:

Part Number |

Description |

| 11583-03-00 | Plastic hose ø8/6 |

| 11583-26-00 | Plastic hose ø6/4 |

| 14491-04-00 | Hose |

| 25542-00-00 | Kit push-in fitting |

| 25542-06-00 | Set of Nipples |

| 25542-07-00 | Hose kit |

| 25542-23-00 | Set of nipples DGL |

| 25542-24-00 | Set of couplings GLS-SE |

| B040F001 | Coupling |

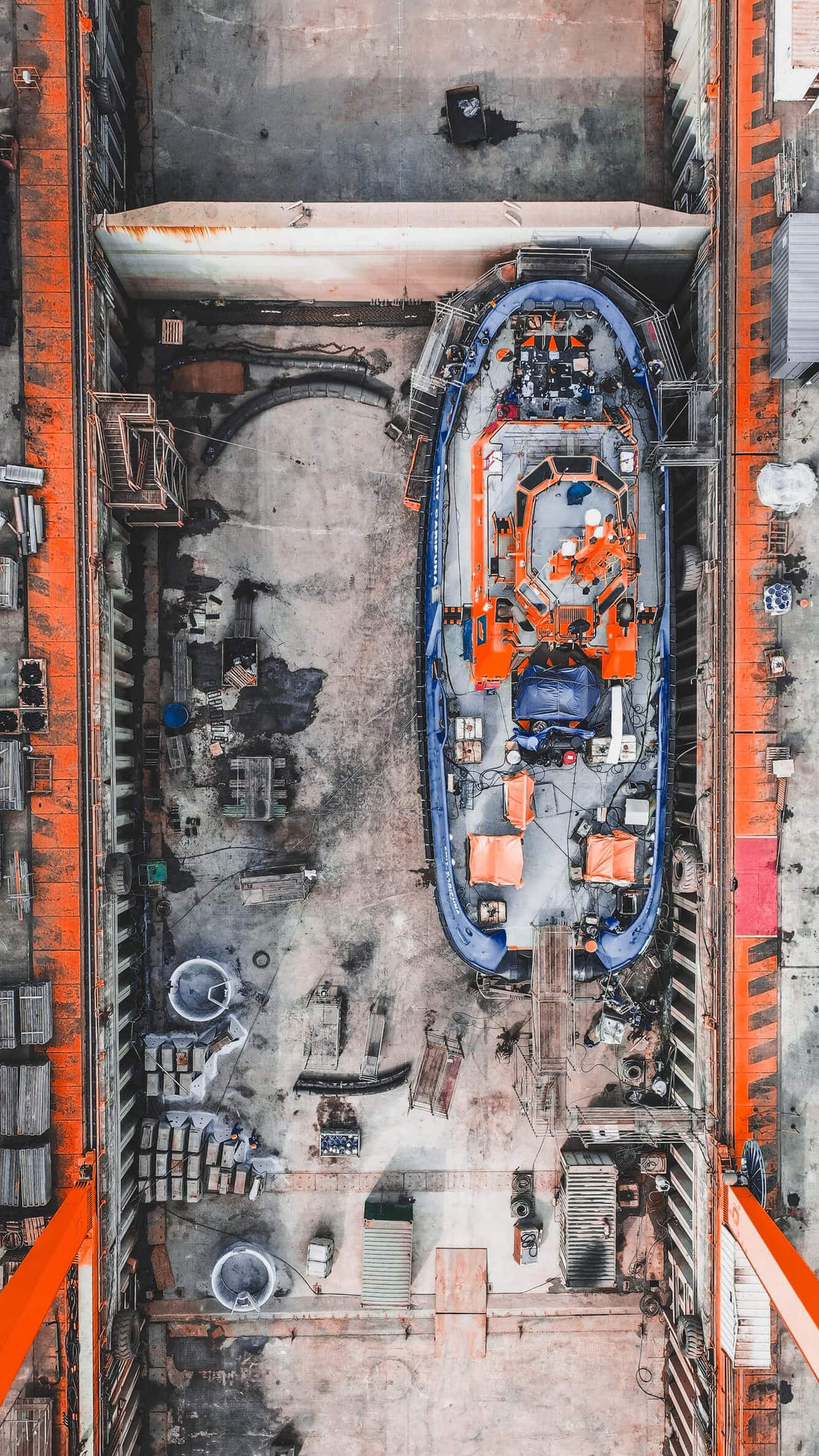

Portable Hydraulic Power Units for all hydraulic tools.

LEMAG PEAKmag® Pressure Indicators

The LEMAG PEAKmag® serves as a basic yet essential pressure indicator that measures the maximum ring pressure in internal combustion engines. It protects users by providing accurate readings, especially in cases of excessive cylinder pressure.

Benefits of Using LEMAG PEAKmag®

Utilizing the LEMAG PEAKmag® offers several advantages. First, it optimizes engine performance by ensuring that the engine operates within safe pressure limits. Consequently, this helps prevent unbalanced operation, which can lead to significant wear and tear on engine components. Additionally, it effectively avoids uncontrolled vibrations, reducing the risk of costly breakdowns. Most importantly, the indicator helps maintain efficiency, thereby optimizing fuel consumption.

In summary, the LEMAG PEAKmag® is a robust and reliable tool that enhances engine efficiency and safety. Choose this pressure indicator for precise monitoring and optimal performance in internal combustion engines.

Contact Us for More Information

If you have any questions or require spare parts for your Chris-Marine system.

Product Features

The indicator boasts an impressive pressure range of up to 250 bar (3000 psi). This wide range allows for versatile applications across various engine types. Key features include:

- Optimized Engine Performance: Ensures the engine operates efficiently within safe pressure limits.

- Fuel Consumption Efficiency: Helps maintain optimal fuel usage by preventing pressure-related inefficiencies.

- Prevention of Unbalanced Engine Operation: Displays critical data to avoid uneven performance across engine components.

- Loss of Efficiency Prevention: Minimizes the risk of decreased performance due to pressure anomalies.

- Vibration Control: Aids in avoiding uncontrolled vibrations, thus protecting engine integrity.

- Easy Handling: Designed for user convenience, ensuring simple operation in any environment.

- Safe and Reliable: Built to meet stringent safety standards, providing peace of mind during use.

- German Precision Technology: Manufactured using advanced techniques to guarantee high-quality performance.

LEMAG® LS Pressure Indicators

The LEMAG® LS is a fundamental pressure indicator designed to measure the maximum ring pressure in internal combustion engines. Built with user safety in mind, it provides precise readings to protect against excessive cylinder pressure.

Benefits of Using LEMAG® LS

Using the LEMAG® LS offers several key advantages. It helps optimize engine performance by ensuring balanced pressure levels, preventing engine imbalance and wear. Additionally, it reduces uncontrolled vibrations, which minimizes the risk of breakdowns and costly repairs. By maintaining consistent engine pressure, the indicator ensures efficient operation and helps optimize fuel consumption.

In conclusion, the LEMAG® LS is a reliable and robust pressure indicator, designed to optimize internal combustion engine performance while ensuring safety and fuel efficiency. Choose Chris-Marine for accurate pressure measurement and dependable engine monitoring.

Contact Us for More Information

If you have any questions or require spare parts for your Chris-Marine system.

Product Features

The indicator boasts an impressive pressure range of up to 250 bar (3000 psi). This wide range allows for versatile applications across various engine types. Key features include:

- Optimized Engine Performance: Ensures the engine operates efficiently within safe pressure limits.

- Fuel Consumption Efficiency: Helps maintain optimal fuel usage by preventing pressure-related inefficiencies.

- Prevention of Unbalanced Engine Operation: Displays critical data to avoid uneven performance across engine components.

- Loss of Efficiency Prevention: Minimizes the risk of decreased performance due to pressure anomalies.

- Vibration Control: Aids in avoiding uncontrolled vibrations, thus protecting engine integrity.

- Easy Handling: Designed for user convenience, ensuring simple operation in any environment.

- Safe and Reliable: Built to meet stringent safety standards, providing peace of mind during use.

- German Precision Technology: Manufactured using advanced techniques to guarantee high-quality performance.