KC Ltd.

KC Ltd. – Products

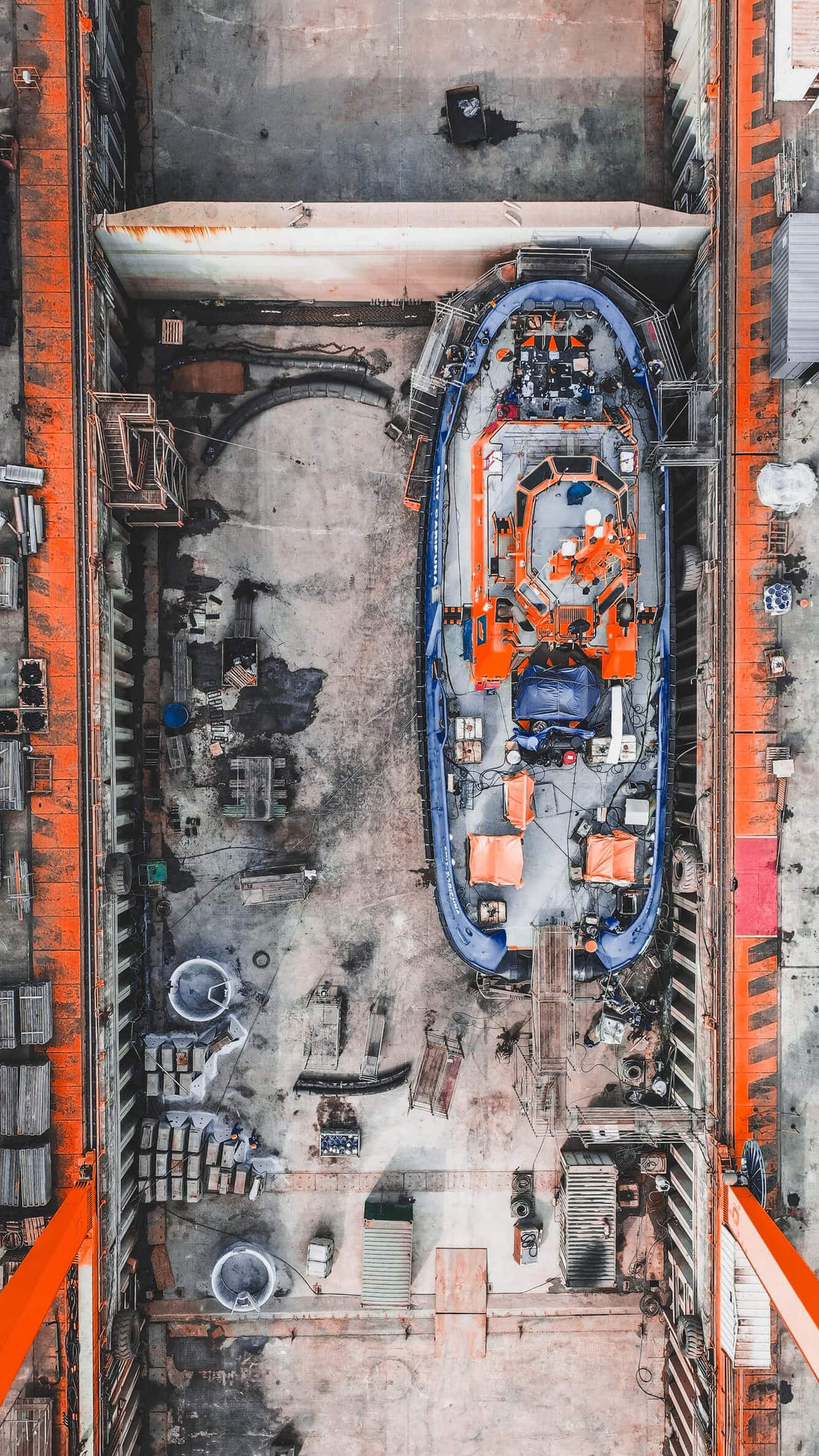

CATHSYS® I.C.C.P. System: Efficient Hull Corrosion Protection

The CATHSYS® Impressed Current Cathodic Protection (I.C.C.P.) system is designed based on the ship’s total wetted surface area, including the rudder and propeller, and mean current density. While high-quality anti-corrosion paints are applied to protect the hull, these coatings can degrade over time due to harsh seawater conditions. When hull paint becomes damaged, the I.C.C.P. system provides essential protection by preventing corrosion.

Automatic and Manual Control for Optimal Protection

The CATHSYS® I.C.C.P. system automatically monitors and controls the electric potential of the ship’s steel hull using reference cells. These cells detect changes in potential, and the system adjusts the protective current accordingly, eliminating the need for sacrificial anodes. This automatic control not only reduces maintenance costs but also extends the time between dry docks. For added flexibility, operators can switch to manual mode to set protective current levels as needed.

To ensure system efficiency, ship engineers regularly send monthly log sheets via fax or email. Our team offers complimentary professional system diagnostics and reports to verify optimal operation.

With its advanced controls and user-friendly interface, CATHSYS® I.C.C.P. is a reliable solution for protecting ship hulls from corrosion, ensuring long-term performance and cost savings.

Contact Us for More Information

If you have any questions or require spare parts for your K.C. ltd. system.

Key Features of the CATHSYS® I.C.C.P. System

- Automatic and manual control modes

- Touch-screen LCD display for easy operation

- Data download capability via USB memory

- Seamless integration with ship’s AMS for alarms and data communication

- Simple installation for both newbuild and retrofitted ships

ANFOSYS® Anti-Fouling System (M.G.P.S.): Effective Marine Growth and Corrosion Prevention

The ANFOSYS® Marine Growth Prevention System (M.G.P.S.) is specifically designed to eliminate marine bio-fouling and suppress corrosion in seawater pipelines efficiently. By basing its design on factors such as ship flow rate, lifetime, and dosing rate (ppb), it ensures optimal protection. The system leverages Cu anodes, which release copper ions to prevent marine growth, while AI/Fe anodes create an anti-corrosive layer to reduce corrosion, safeguarding the ship’s pipeline infrastructure.

The selection of anodes depends on the material of the pipeline:

- Cu-Al anode: Suited for steel pipelines.

- Cu-Fe anode: Ideal for non-steel (Cu-Ni) pipelines.

Flexible Installation Options

The ANFOSYS® system offers flexibility in anode installation with three typical methods:

- Sea Chest Installation: In this method, the anodes are placed in the sea chest (Case 1). While effective, this setup requires renewal and inspection during dry dock, which may limit convenience.

- Strainer Installation: This method (Case 2) places anodes in the strainer, allowing maintenance while the vessel is afloat. However, the sea chest and the inlet pipe up to the filter remain unprotected and require regular cleaning during dry dock.

- Anode Treatment Tank Installation: Anodes are installed in a separate treatment tank (Case 3). Ionized seawater is then injected into the sea chests, making maintenance easier and enhancing system control.

Key Advantages of ANFOSYS®

The ANFOSYS® system offers a reliable and cost-effective solution for preventing bio-fouling and corrosion. It also extends the lifespan of marine vessels through consistent, low dosing and adaptable installation methods. By ensuring minimal maintenance, it enhances vessel efficiency and ensures long-term operational performance.

Contact Us for More Information

If you have any questions or require spare parts for your K.C. Ltd. system.

Key Features of the ANFOSYS® M.G.P.S.

- Automatic current adjustment based on 2- or 3-step flow operations.

- Low installation and maintenance costs.

- Environmentally friendly, with a typical dosing rate of 2ppb copper ions.

- User-friendly and sophisticated controller for convenient operation.

- Integration with the ship’s AMS for data communication and alarm signals.

- Easy installation for both new builds and retrofit ships.

CATHSED® Shaft Earthing Device: Advanced Protection Against Shaft Corrosion

The CATHSED® Shaft Earthing (Grounding) Device is engineered to meet specific ship requirements, including intermediate shaft diameter and quantity. When a ship’s propeller shaft turns, it becomes electrically insulated from the hull due to the lubricating oil film in the bearings and non-metallic bearing materials in the tail shaft. This insulation creates an electrical potential between the shaft and hull, accelerating corrosion. Additionally, the shaft insulation hinders the propeller and boss from receiving cathodic protection, whether through sacrificial anodes or an impressed current system.

This electrical potential can cause heavy currents to flow through the bearings when the oil film breaks down or becomes contaminated with seawater, leading to severe bearing pitting. Over time, excessive wear on the shaft bearings can occur. By properly grounding the shaft with a propeller shaft slip ring, you can extend cathodic protection to the propeller and avoid these issues.

Innovative Features for Long-Lasting Performance

The CATHSED® Shaft Earthing Device uses high silver content brushes running on a silver alloy slip ring to ensure consistent low conductivity, even in dirty conditions. The assembly features high silver/graphite compound brushes mounted in balanced brush holders. Each brush holder includes an adjustable spring tensioner, preset to the standard pressure for optimal performance. This configuration allows the brushes to last over a year, even under challenging conditions such as mechanical friction, sparks from the main engine, or high electrical potential from the stern bearing and propeller.

The earthing readings are continuously monitored via a mV meter, ensuring they remain below recommended levels. K.C. Ltd provides high-quality silver graphite brushes and durable silver slip rings, designed to endure harsh environments and deliver long-lasting performance.

Contact Us for More Information

If you have any questions or require spare parts for your K.C. Ltd. system.

Key Features of the CATHSED® Shaft Earthing Device:

- Compact and lightweight design

- Complies with MAN Diesel requirements

- Monitors both current (Amp) and voltage (mV) readings

- Compatible with ship’s AMS for data communication and alarms

- Simple installation for new builds and retrofitting ships